3. Criteria for selection and use of bearing

Authorized distributor

Find a distributor

Find a distributor

Technical support:

3.1 Types of rolling-contact bearings

ZKl Company manufactures a full range of bearings, from which the designer can choose the bearings that best meet the specific requirements.3.1.1 Based on load direction

Rolling-contact bearings are generally divided according to the direction of force, for whose transfer they are predominantly designed, into two basic groups:

We divide bearings, according to shape, into ball (single-point contact) bearings and roller (line contact) bearings. Contact in ball bearings theoretically occurs at a single point, hence the designation “single-point contact bearings.” In roller, spherical, tapered roller, and needle roller bearings, contact occurs in a line or straight line, resp., thus they are commonly designated as straight-line (vector) or line-contact bearings.

The following overview provides a classification of individual bearing types based on this characteristic.

Single-point contact bearings

Line-contact bearings

We separate each type of roller bearing then into several types according to dimensions and design variations. Specific information on characteristics of individual types of bearings is available in the sections of text provided before the tables of individual bearings.

- Radial bearings

- Axial bearings

We divide bearings, according to shape, into ball (single-point contact) bearings and roller (line contact) bearings. Contact in ball bearings theoretically occurs at a single point, hence the designation “single-point contact bearings.” In roller, spherical, tapered roller, and needle roller bearings, contact occurs in a line or straight line, resp., thus they are commonly designated as straight-line (vector) or line-contact bearings.

The following overview provides a classification of individual bearing types based on this characteristic.

Single-point contact bearings

- Single-row ball bearings (fig. 3.1)

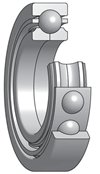

- Single-row angular-contact ball bearing (fig. 3.2)

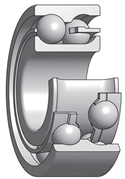

- Double-row angular-contact ball bearing (fig. 3.3)

- Four-point contact bearing (fig. 3.4)

- Double-row, self-aligning ball bearing (fig. 3.5)

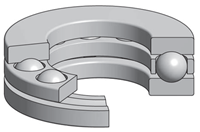

- Thrust ball unidirectional bearing (fig. 3.6)

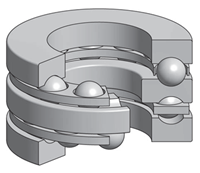

- Thrust ball bidirectional bearing (fig. 3.7)

Fig. 3.1 |

Fig. 3.2 |

Fig. 3.3 |

Fig. 3.4 |

Fig. 3.5 |

Fig. 3.6 |

Fig. 3.7 |

Line-contact bearings

- Single-row roller bearing (fig. 3.8)

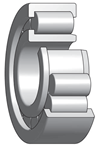

- Double-row roller bearing (fig. 3.9)

- Single-row cage-less roller bearing (fig. 3.10)

- Double-row cage-less roller bearing (fig. 3.11)

- Tapered roller bearing (fig. 3.12)

- Double-row tapered roller bearing (fig. 3.13)

- Double-row spherical roller bearing (fig. 3.14)

- Thrust roller bearing (fig. 3.15)

- Thrust spherical roller bearing (fig. 3.16)

Fig. 3.8 |

Fig. 3.9 |

Fig. 3.10 |

Fig. 3.11 |

Fig. 3.12 |

Fig. 3.13 |

Fig. 3.14 |

Fig. 3.15 |

Fig. 3.16 |

We separate each type of roller bearing then into several types according to dimensions and design variations. Specific information on characteristics of individual types of bearings is available in the sections of text provided before the tables of individual bearings.

3.1.2 Separable and non-separable bearings

Separable bearings allow separate installation of both rings, which is of particular advantage when installing both rings with an overlap. Sequential installation of individual parts can also be used in certain complex housings and assembly units. Separable bearings are, e.g. four-point contact bearings, double-row ball bearings with split inner ring, roller bearings, tapered roller bearings, thrust ball bearings, thrust roller bearings, and spherical roller thrust bearings.

In contrast, non-separable bearings include, e.g. single row ball bearings, single row angular-contact ball bearings, self-aligning ball bearings, and double-row spherical roller bearings.

In contrast, non-separable bearings include, e.g. single row ball bearings, single row angular-contact ball bearings, self-aligning ball bearings, and double-row spherical roller bearings.

3.2 Criteria for selecting bearings

The ZKL production program offers a full range of bearings, from which the designer can choose the bearings that best meet the specific requirements. The bearing type and size are generally chosen according to its loading capacity with consideration to its operating conditions and expected bearing service life. To determine the proper type of bearing thus requires a thorough knowledge of the loading capacity of the bearing during operation. Proper principles for selecting, fitting, and installing them must be followed, but it also requires knowledge of the prerequisites for which the proposed results apply. In the following chapters, we thus present general principles for selecting and using contact-roller bearings, which may be used by drafting engineers in the bearing design process. The chapters are organized in logical consecutive order. The technical part of the publication contains important regarding calculations, design data, housing, lubrication designs, as well as installation and removal information on rolling-contact bearings. The table provides a list of currently manufactured ZKL rolling-contact bearings with main dimensions and functional parameters.Even though they list detailed information, this publication is unable to provide full information on all housings for their wide varieties of application. We therefore recommend that complex housing designs be consulted with ZKL technical and consultation service specialists.