10. Asembly and disassembly of bearings

Find a distributor

10.1 General information

Roller bearings are strongly stressed machine components parts of which feature high accuracy. To be able to utilise fully functional properties of bearings and avoid damaging them before the end of their service life, assembly and potentially disassembly procedures have to be correctly specified. To do so, the structure of location has to be well known, suitable workplace and assembly tools made available to simplify the assembly and disassembly of bearings. It is very important that the assembly is performed by workers who are properly qualified and equipped with protective equipment.10.2 Assembly worksite

Worksite must be equipped with suitable assembly tools and jigs to make the work comfortable and also safe. Equipment varies by the type and size of bearings to be assembled at the worksite. Very important is to make sure that these tools are clean and the work is performed in a clean working environment. In negative sense, impurities have decisive impact on the run of bearing when it is in service. Depending on the size and origin of impurities they may cause increased noise level of bearing and may also cause a bearing failure. The same conditions of cleanliness have to be applied in the preparation of all lubricating agents and components associated with location. Assembly worksite has to be therefore separated from normal production and only reserved for assembly of bearings. The worksite must be sufficiently spacious, dry and dust-free. No adjustments of components are supposed to be performed there, such as polishing, drilling or welding that could cause impurities to penetrate into the location area, or no air compressing devices shall be used in the proximity. The worksite shall not be exposed to weather effect since bearings are very sensitive to humidity, especially after being washed off preservative agents or old lubricant.10.3 Work procedures

Prior to the commencement of every assembly the work procedure has to be specified based on drawing documentation to define individual work steps. In special cases that differ from common practice, detailed assembly instructions have to provided, containing all assembly details, such as specification of needed work tools and equipment for assembly and disassembly, measuring instruments, special tooling, way of heating the bearings up, type and amount of lubrication, etc.10.4 Preparation of bearings for assembly

Prior to the assembly, the fitter has to make sure whether the designation stated on the bearing corresponds with that on the bearing packaging stated on the drawing. The fitter should have basic knowledge of roller bearing identification system.ZKL bearings are in original packaging protected with a preservative agent against corrosion for a period of 5 years on condition of proper storage. In order to maintain cleanliness, bearings are taken out of the packaging just before the assembly. Only in exceptional cases the bearing is cleared of preservative agent. Damaged packaging indicated potential contamination of bearings during the storage; so the bearings always have to be washed out prior to the assembly. Various cleaning agents can be used to wash out bearings – organic or inorganic. One can use e.g. benzine with 5 to 10% addition of oil, petroleum, alcohol or dehydrating fluids. Majority of these agents are flammables – this have to be borne in mind. An alternative are alkaline cleaning agents but these are caustic substances.

Bearings are washed out in a clean suitable tank using a brush or a fibre-free cloth. During the washout one of the bearing races have to be rotated with. If one bath is not sufficient to wash out the bearing, multiple baths are used depending on the level of contamination. After the washout, the bearing has to be provided with protective oil or grease layer depending on the type of lubrication to be used in run. During preservation, one race of the bearing is slowly rotated with so that the orbits of both races as well as the surface of rolling bodies come to contact with the preservative agent.

After preservation, the bearing has to be protected from contamination and mounted to respective place as soon as possible. The anticorrosive agent that is used for preservation of ZKL bearings is compatible with majority of commonly used plastic lubricants and need not be removed before the assembly. It is only recommended to wipe the surface and hole of the bearing to ensure proper location of the bearing.

No additional mechanical adjustment shall be done on roller bearings, such as making holes for supply of lubricant, slots, recesses, etc., since this might release tension in the races that would cause early damage to the bearing. Besides that, there is a risk that the bearing can be contaminated with splinters or abrasion dust.

When handling bearings one needs to use gloves and lifting equipment to simplify the operation and enhance work safety. If you need to lift bearings in vertical position, we recommend to suspend them on a steel belt or strap on the outer race circumference and not in one spot only. To lift bearings in horizontal position we recommend that big bearings are, upon a special request, provided with tapped holes for lifting lugs that will simplify subsequent handling. Suspension screws must however be loaded exclusively in the direction of the shank axis.

10.5 Preparation of location components for assembly

Prior to the assembly, all located parts must be thoroughly clean and cleared of burrs caused during their machining. Unmachined surfaces of the inside of rolling location bodies must be perfectly clean and cleared of the moulding sand residues, and provided with a protective coating. Also, all lubrication holes and threads have to be cleared thoroughly. All sharp edges need to be bevelled.

Prior to the assembly itself you need to check that the defined tolerances, geometrical accuracy and quality of bearing saddle surface and that in the body have been met. The accuracy of rolling bodies' dimensions need not checked prior to the assembly.

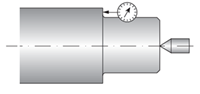

To ensure reliable operation of bearings, bearings must not be mounted on shafts which do not guarantee the accuracy of geometrical shape, on bended shafts or on shafts with mechanical damage. Therefore the shaft has to be checked carefully prior to the assembly. Depending on the size of the shaft, the accuracy of shape in tips can be checked on the lathe (Fig. 10.1) or in supports by means of pointer indicator or micrometer.

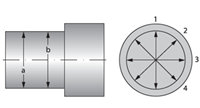

Cylindrical journal can be checked using a snap gauge or micrometer in two planes perpendicular towards the journal axis. Two measurements are to be performed in each plane (Fig.10.2).

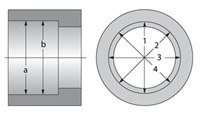

Additionally, the fitting and fillet of transit on the shaft have to be checked. It is very important that the perpendicularity of fitting the frontals towards to cylindrical seating surface axis for bearings was as accurate as possible. Bearing race must seat with the entire surface on the front surfaces of the support. Major deviations of frontal surface perpendicularity cause additional tensions in bearings and race deformation when the races are pressed on and in axial load. At higher revolution frequencies these strains negatively affect the run of the bearing. The method of measuring the perpendicularity of the fitting forefront is indicated in Fig.10.3.

Tapered journals are checked by taper gauge (mostly taper 1:12) which has to be seated on the entire surface.

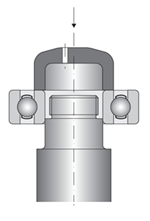

Bearing bodies are checked in the same way as journals (Fig.10.4) using an internal micrometer or a gauge. We also check the concentricity of seating surfaces in the body, especially if ball and roller bearings are mounted. Split cases have to be checked for not forming a hole on the body after tightening the connecting screws which would result in undesirable gripping and deformation of the outer race of the bearing.

Fig. 10.1 |

Fig. 10.2 |

Fig. 10.3 |

Fig. 10.4 |

It is recommended to record the results of measuring. During the measuring it has to be made sure that the measured parts and measuring instruments have approximately the same temperature. This is of special importance when big and heavy bearings and related parts are measured.

We also recommend that prior to the assembly the locations of bearings are provided with mounting lubricant. Mounting lubricant can be used for any fixed and sliding locations. It simplifies the assembly itself, prevents occurrence of joint corrosion and makes easier subsequent disassembly of the bearing from location.

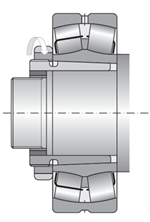

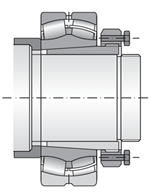

10.6 Assembly of bearings with cylindrical bore

Different types and sizes of roller bearings require different assembly procedure. In principle, direct hammer strokes on the race (ring) collars, on cages or rolling bodies have to be avoided during the assembly. When assembling non-separable bearings, the mounting force must act on the race located with overlap that is mounted as first. In no case shall the mounting force be transferred via the rolling bodies of the bearings. Thus the bearing is firstly mounted on journal by loading via the inner race and then the entire bearing is pushed in the body where the location is usually sliding (Fig. 10.5). If a non-separable bearing with overlap on shaft and in body is mounted, the mounting force must act on both races equally (Fig. 10.6). Races of separable bearings can be assembled separately.

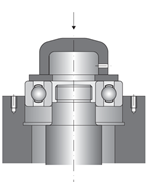

Fig. 10.5 |

Fig. 10.6 |

Bearings are mounted in location units either cold or heated.

10.6.1 Cold assembly

10.6.2 Hot assembly

Hot assembly is used for bigger bearings races of which are usually located with higher overlap. During the process, inner races, alternatively entire bearings and bodies in which the bearings are mounted, are heated up prior to the assembly. We recommend that the assembly procedure with bearing temperature heat-up above 100 °C is discussed with the workers of the ZKL technical and consultancy services.

To ensure fast, safe and clean heat-up of bearings it is recommended to use induction heating equipment to ensure uniform heating of bearings without the risk of local overheating. Individual bearings of smaller dimensions can be heated on electrical hot plate with thermostatic control. Bearings have to be turned several times during the heating. Medium sized bearings can be heated by hot air reheat case with thermostatic control. The time of heating is however relatively long.

Roller bearings of all types and sizes can be heated in oil bath (Fig.10.7). This way of heating does not suit heating of sealed bearings, bearings with plastic lubricant filler and accurate bearings. Oil filler should be provided with thermostatic control (temperature between 80 and 100ºC) but usual heating is 50 to 60 ºC above ambient temperature, i.e. oil is heated up to 70 to 80 ºC. In the bath, bearings have to be placed on a grid or suspended in the bath to avoid their direct contact with the heated surface which might lead to overheating. Heating in oil bath however has a number of disadvantages, mostly the risk of injury, pollutant load with oil vapours, risk of hot oil inflammation and risk of bearing contamination.

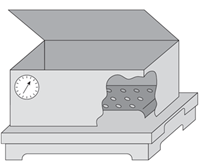

Fig. 10.7

10.7 Assembly of bearings with tapered bore

Bearings with tapered hole (bore) are mounted on shaft by means of clamp or dismantling sleeves, or alternatively directly on tapered journal. Inner race with tapered bore is always placed on the journal firmer than a race with cylindrical bore. Fixed location is achieved either by pressing the inner race on by means of a nut or a tapered sleeve. In both cases the inner race will expand and cause reduction of radial clearance in the bearing. Therefore a method has to be determined that would correctly specify the overlap. This can be achieved by measuring the radial clearance reduction using a feeler gauge. The clearance before and after assembly must be measured between the inner race and unloaded rolling body. This method suits to medium size and big spherical-roller bearings. Other methods are e.g. measuring of the lock nut torque angle or measuring of axial displacement of the inner race on the tapered journal. In the assembly of double row tilting ball bearings, the clamp bushing nut can be tightened to such extent that the inner ring can be smoothly turned and tilted. The assembly method should be consulted with the manufacturer.

Reliability of fixation of spherical-roller bearings can be checked by measuring of axial displacement of the inner race on the journal or tapered sleeve. The initial position for measuring of this displacement will be achieved when the contact surfaces (of the race, sleeve, shaft) abut against each other on the entire bearing surface. The values of axial displacement for the assembly of double row spherical-roller bearings with tapered bore are stated in chart 5, chapter Spherical-roller bearings.

Small bearings of bore diameter up to 80 mm can be pressed on a tapered journal, clamp bushing (Fig. 10.8) or on the dismantling sleeve (Fig. 10.9) by means of terminal nut that is tightened by a mounting spanner. Prior to the assembly, the contact surfaces have to be coated by oil.

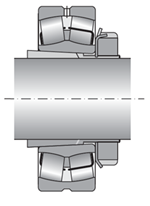

Fig. 10.8 |

Fig. 10.9 |

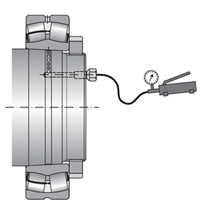

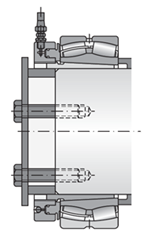

Bigger bearings require much bigger mounting force, and that’s why hydraulic nut or pressure oil method should be applied in their assembly, when oil is brought between the contact surfaces of the race and journal under high pressure (Fig. 10.10). This creates an oil film that reduces friction between the bearing surfaces. This method can be used also for the assembly onto clamp bushings or dismantling sleeves that are modified to suit this method. Use of oil of 75 mm2/s viscosity at 20ºC is recommended for the assembly (nominal viscosity at 40ºC is 32mm2/s).

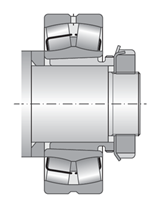

Fig. 10.10

10.8 Disassembly of bearings with cylindrical bore

If bearings and related parts are to be reused, the disassembly has to be paid particular attention. Non-separable bearing is always dismantled by force acting on the race located with overlap. In separable bearings they are dismantled one by one, analogically with the assembly of these bearings.

For disassembly of smaller bearings mechanical pullers or hydraulic presses (Fig. 10.1) should be used. The disassembly can be simplified by means of a groove on the shaft or in the body that will allow engagement of the puller on the race mounted with overlap. To dismantle inner races of heat mounted roller bearings one should use induction tools.

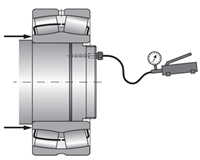

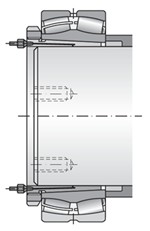

To dismantle bearings with fixed location on cylindrical journal also the procedure using pressure oil can be applied (Fig. 10.12). This method significantly simplifies the disassembly in cases when big pulling force would have to be applied. The use of this method requires provision of a location with canals and distribution grooves for supply of pressure oil in the bearing inner race location. The supplied oil significantly reduced the force necessary for bearing disassembly that has to be performed with the help of suitable dismantling equipment, even if this method is applied. Once the oil separates the surfaces of the bearing location which becomes obvious when the oil starts infiltrating, we will pull the bearing down rapidly, without an interruption. If the bearing blocks once the oil canal on the shaft gets partially uncovered, we either have to heat it, or pull down applying considerable force by means of hydraulic tooling.

Fig. 10.11 |

Fig. 10.12 |

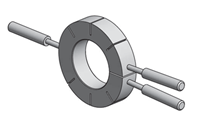

To disassembly inner races of roller bearings without guide flanges or with one guide flange also heating rings can be used (the so-called thermo rings). These are tools made of light alloy, provided with radial grooves (Fig. 10.13). This alternative is a cheaper option to induction equipment, mainly for dismantling of bearings with bore diameter exceeding 400 mm, or bearings that are dismantled only sometimes. A thermo ring is heated on an electrical hot place to the temperature of 280ºC approximately, slipped over a dismantled bearing ring and clamped in grips. After pulling the roller bearing inner race off the journal, the race has to be taken off the thermo ring immediately to prevent if from overheating.

Fig. 10.13

10.9 Disassembly of bearings with tapered bore

If a bearing is mounted on a tapered journal or on a clamp bushing, first the lock of the terminal nut or the bushing nut has to be removed. The nut is loosened by the distance necessary to release the bearing. Alternatively, another holdback can be used. After pulled down from the tapered journal the bearing will release at a swoop, and without this holdback there is a risk that the bearing will fall down of the shaft.

Disassembly of small and medium size bearings off tapered journal proceeds often by means of pullers that are fastened by the inner race of the bearing or a support part, such as labyrinth ring. Already when designing the location the layout of suitable holes or grooves for puller arms should be considered. Inner races of small bearings can be pulled down by means of press or hammer and spine. If press is used, the clamp bushing has to be leaned and force applied on the inner bearing race (Fig. 10.14).

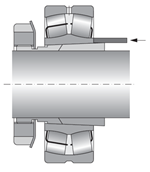

Bearings that are fastened by means of a clamp bushing are dismantled by means of terminal nut (Fig. 10.15). When big bearings are dismantled and therefore bigger force has to be applied, trust screws guided by nut can be used (Fig. 10.16). A washer has to be put between the inner bearing race and the screws in order to prevent damage of the bearing. Very fast, simple and economic is disassembly of clamp bushing by means of hydraulic nut. If the bearing is on the edge of the journal, it is recommended that the hydraulic nut is before the disassembly locked with a jig fastened e.g. to the front of the shaft (Fig. 10.17).

Big clamp bushings usually have canals and grooves for pressure oil. Oil is thus supplied directly by the pulling nut between the shaft and the bushing, and between the bushing and the bearing (Fig. 10.18). After pressurised, contact surfaces can be shifted against each other without a risk of damage. Needed pressure is achieved by oil injectors. For the disassembly oil with low viscosity is used, approx. 150 mm2/s at 20ºC is required (nominal viscosity at 40ºC is 46 mm2/s).

Fig. 10.14 |

Fig. 10.15 |

Fig. 10.16 |

Fig. 10.17 |

Fig. 10.18 |

10.10 Storage of bearings

ZKL bearings are stored and packed in a way that maintains the properties of the bearings as long as possible. The prerequisite for achieving these goals is achieving the conditions for storage of bearings and handling them.Relative air humidity in the storage should not exceed 60%, and there should be no major temperature oscillations. Most convenient temperature range for storage of bearing is between 15 and 25ºC.

Bearings should not be exposed to vibrations and shocks. When stored, bearings must not be exposed to aggressive media, such as gases, fog or aerosols of acids, lyes and salts. Also the effect of direct sunlight has to be prevented since it may cause major temperature oscillations in the container. Big bearings, especially those of light series, must not be stored as standing. They should be placed horizontally to avoid deformation of races (rings). Bearings must not be stored in racks made of fresh timber or on a stone floor. Bearings must not be placed in the proximity of heating or water piping.

10.10.1 Storage period

If the admissible storage terms are exceeded we recommended that bearings are checked in terms of preservation and corrosion.

If possible, both-side covered (2Z) or sealed (2RS) bearings should not be stored until the end of the storage term. During the storage, plastic lubricant filler may get old due to chemical and physical processes. Bearings can be functional but the lubricant may be useless. The recommended time of storage of bearings with plastic lubricant is two years.